Merit Brass is committed to partnering with vendors who share our commitment to providing consistent, high-quality valves which are vital to the pipeline's sustainability. As you know, piping systems rely on quality connections that serve the needs of the application and valves play a key role in throttling the flow of any system.

Valves are devices that control, regulate, or direct flow of liquids and gas within various systems. A valve helps manage the pipeline by opening, closing, or partially blocking the flow. Valves come in many forms to fit the needs throughout several industry applications including commercial and residential plumbing, water and wastewater treatment, pharmaceutical, power generation, oil and gas, and so much more. It’s important to understand that the valve you choose impacts the overall performance within the application. This includes how much control you have over the flow and how the valve operates.

Two of the most common types of valve openings include quarter turn valve and multi-turn valves. Quarter-turn valves fully open or close with a 90-degree turn. Multi-turn valves open or close by turning the valve handle or hand wheel; these valves must be turned multiple times to fully open or close.

Furthermore, it’s important to understand the different types of valves and their functions to help determine which will be the most ideal for your application. Some of the most common types of valves include: ball (full port, standard port, reduced port), gate, check (including swing check and y-pattern swing check), butterfly, globe, pressure relief and instrumentation. The most commonly used is the gate valve.

For ball valves, the type of port the valve has determines the flow throughout the system. There are 3 common types: standard port, reduced port and full port.

Full Port – the valve has an oversized ball so the hole in the port is the same as the inner diameter (ID) of the pipeline; there is 100% flow through the pipeline.

Standard Port – the valve has a smaller port than the ID of the pipeline; there is about 75% of flow through the pipeline.

Reduced Port – the valve has an even smaller port than the ID of the pipeline; there is about 65% of flow through the pipeline.

Another feature in valves to consider is the valve’s end connection. The valve end connection must be compatible with your piping system. Some of the most common types of valve end connections include:

At Merit Brass, our valves are available in several alloys: Stainless steel, brass and copper. Our stainless steel valves are corrosion resistant. We carry several types of valves in stainless steel including our "K" Series, "V" Series, Instrumentation and our engineered solution, StainlessPress®.

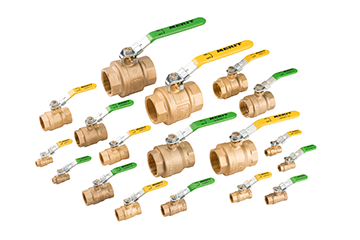

Our brass valve offering is comprised of ball valves. Merit carries both leaded and lead-free. Lead-free can serve your potable water applications.

Excellent Corrosion Resistance to Water and Heat

Resists Attack from Salt Water, Acid, Minerals, and Peaty Soils Contained in Water

600PSI Non-Shock WOG 125 PSI SWP Rating

Conforms to MSS-SP-110

Threaded Ends ANSI B1.20.1

CSA Gas Approved for Valves up to 2” (IPS only)

Lead free is compliant to NSF61 and suitable for potable water applications

Lead free 2-½” - 4” is UL/FM Approved

Standard, full and reduced ports

Y-strainers

Gate valves

Threaded, socket weld

Standard, full

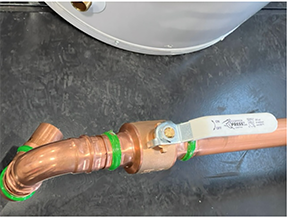

Merit's CopperPress® valves come with a 5-year limited warranty. The CopperPress® valve is designed to be used with ASTM B88 Type K, L and M copper tubing.

2-Piece Ball Valve: ½” – 2”

Patented VIPR® Band (Visual Indicator Press Ring®) facilitates immediate identification of unpressed connections

Maximum working pressure: 300 psi

Leak Before Press (LBP) System

FAQ

LEARN MORE