Press fittings (also known as press-connect fittings) have become increasingly popular in HVAC applications due to their ease of installation, efficiency, and durability. Press fitting systems reduce project costs by 30-50% due to labor and auxiliary material savings. Press fittings reduce the time it takes to install a system, address labor shortages, have reduced overhead costs, and are safe to use.

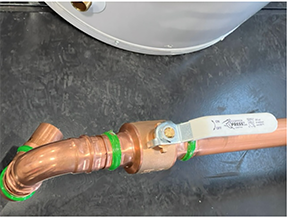

Safety is key which is why there is no need to acquire an open flame permit with press fittings and valves. All that is required with a press system are the press fittings and/or valves, a press tool, and the accompanying press jaws/rings. The press tool joins pipes or tubes to the fitting and/or valve without the need for welding or soldering.

Press fittings are commonly used in HVAC applications to connect copper tubing for gas lines, water pipes, and refrigerant lines. They are an ideal choice for HVAC installations because they can be easily installed in tight spaces, they reduce the need for extensive piping, and they make it possible to install HVAC systems in locations that were impossible before.

Press fitting systems work by using a press tool to compress the fitting onto the pipe or tube. This creates a secure, leak proof seal. The connection is tight and reliable because the fittings are designed with a sealing element. Merit’s sealing elements have a 3-Path Leak Before Press System for ½” copper and a 4-Path Leak Before Press System for ¾” – 2” copper.

In HVAC applications, one of the primary benefits of using press fittings is their efficiency. Unlike traditional welding or soldering methods, press fittings can be installed quickly and easily with minimal preparation. So, if your project is on a tight deadline or you have limited access, press is an ideal solution for you.

It is essential for HVAC applications to have a high degree of durability which is why press systems are a great solution. These systems can withstand extreme temperatures, pressure, and vibration. This ensures that over time they will be consistently reliable.

Beyond durability and ease of installation, press fittings are highly customizable. They allow HVAC processionals the ability to select the perfect fitting for their specific needs since press comes in a wide range of sizes and materials.

Overall, press systems have become a popular choice for HVAC professionals and their applications due to ease of installation, efficiency, durability, and the vast array of customizable options. Using these fittings and valves enables HVAC professions to complete installations quickly and reliably. This saves time and money without sacrificing high quality.

Merit has the most comprehensive package of copper press fittings and valves known as CopperPress®. Our offering is available in ½” – 4” with an EPDM sealing element. CopperPress® has a Leak Before Press System (LBP). This creates a permanent pipe joint that is durable when the fitting and pipe are pressed together.

The sealing element also creates a leak-proof joint when it is compressed. If the press fitting or press valve was improperly pressed, the system would leak due to the Leak Before Press System (LBP). This would enable the installer to identify the incorrectly installed fittings very easily because the liquids and gases would leak. The Leak-Before-Press feature significantly reduces the chance of improper joints, helping to ensure a leak-free system.

To help make installation easier, we designed and patented our Visual Indicator Press Ring® (VIPR®) which helps the installer identify any unpressed joints in the system. Each press fitting and valve up to 2" has a Visual Indicator Press Ring® (VIPR®) that mirrors the sealing element and ensures proper installation. The ring can be easily removed after the fitting has been pressed.

EXPLORE YOUR COPPER PRESS INVENTORY NEEDS

Authors: Authors: Kimberly Wallingford, Director of Marketing and Marcus Estrella, Director of Product Line Management

3/28/2025 1:25:26 PM