Press Fittings were first developed in Europe during the 1950s. From that point on, the use of Press Fittings has grown dramatically, and expanded beyond its original Copper/Plumbing applications. Today you can find Press Fittings in multiple industries/applications that require pipes, and tubes, to carry media.

With multiple Press Fitting and Press Tool Manufacturers producing quality products today, it can be a bit overwhelming when trying to understand what the differences are; and what all of this information means. Different materials, different Press Profiles, and different Press Tools can lead to a lot of confusion.

What are Pressing Tools?

What are Pressing Tools?The difference in material characteristics of the Copper, Stainless Steel, and Carbon Steel Press Fittings across all major manufacturers is negligible. Meaning the Carbon Steel material used by Manufacturer A for their Press Fitting is not very dissimilar to the Carbon Steel material used by Manufacturer B for their Press Fitting. Press Tooling Manufacturers know this and have designed their Tools with this knowledge. Press Tools are based on a certain “Pressing Force” to overcome the properties of the Press Fitting Materials, so their Tools can correctly Press the Fittings. This means that if a Press Tool can be used to install a Carbon Steel Press Fitting from Manufacturer A, that same Tool can be used to install the same Carbon Steel Fitting (Product Type and Size) from Manufacturer B.

Press Tools come in a variety of styles, as each one has a different Pressing Force it can apply. This Force, along with the Stroke Length of the internal Piston, directly determines what type of Press Fittings it can be used with.

| Copper | ||

| Force | Stroke | Size Range |

| 15kN | 32mm | 0.5" - 0.75" |

| 24kN | 32mm | 0.5" -1.25" |

| 32kN | 40mm | 0.5" - 4" |

| Carbon | ||

| Force | Stroke | Size Range |

| 24kN | 32mm | 0.5" - 1" |

| 32kN | 40mm | 0.5" - 2" |

| 32kN | 80mm | 0.5" - 4" |

| Stainless Steel | ||

| Force | Stroke | Size Range |

| 24kN | 32mm | 0.5" - 1.25" |

| 32kN | 40mm | 0.5" - 1.25" |

| 32kN | 80mm | 0.5" - 4" |

| 120kN | 60mm | up to 6" |

Note: The Tables above are a general representation of multiple Press Tool Manufacturers’ capabilities. With the addition of various Boosters, and other attachments, Size Ranges may differ from these figures.

Note: The Tables above are a general representation of multiple Press Tool Manufacturers’ capabilities. With the addition of various Boosters, and other attachments, Size Ranges may differ from these figures.

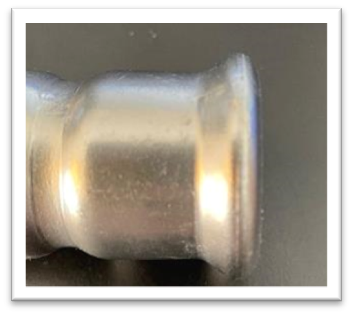

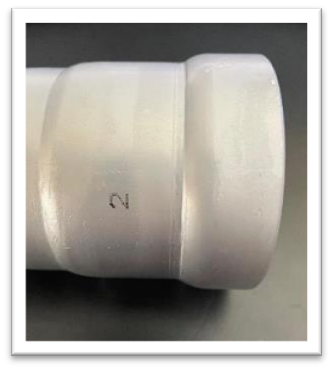

While Press Tools may be interchangeable, Press Jaws are not. To start, Copper Tube Size (CTS) and Iron Pipe Size (IPS) have different diameters for the same Nominal Dimension. Looking at a piece of 1” CTS Copper Tube, it will have an outside diameter of 1.125”, while a 1” IPS Stainless Steel Pipe has an outside diameter of 1.315”. In addition to this, there are 3 main types of Press Profiles which can be used on either CTS or IPS Tube/Pipe:

|

V-Profile

|

|

M-Profile

|

|

Grab-Ring Profile

|

Determining factors as to why a certain Profile is used over another are generally based on the malleability of the Tube/Pipe material, and the Size of the Tube/Pipe.

Smaller diameter Copper Press Fittings (0.5”-2”) utilize the Tube/Fitting deformation to create Metal-to-Metal contact, and do not need the added strength a Grab-Ring provides. However, larger diameter Copper Press Fittings (2.5”-4”) predominantly utilize a Grab-Ring to provide added strength.

Stainless

StainlessSchedule 5 & Schedule 10 Stainless Steel Pipe is malleable enough where the Stainless Press Fittings can be secured with either Metal-to-Metal contact, or through the use of a Grab-Ring; and as a result, utilizes all 3 of the Press Profiles.

Sch 40 Stainless Steel Pipe is not as malleable, and therefore requires the use of a Grab-Ring Profile.

Carbon Steel Pipe does not deform as much as Copper Tube, or Stainless Steel Pipe. Therefore, Carbon Press Fittings are secured with a Grab-Ring on IPS Pipe sizes 0.5”-4” to ensure a secure connection.

Even though Press has been around for over 50 years, there still exists a lot of questions surrounding it. Thankfully, many Manufacturers have comprehensive information listed on their websites to help answer any questions that may come up; but remembering the basics covered in this overview will help answer many of those that you may have.

DISCOVER PRESS AS YOUR SOLUTION

Author: Marcus Estrella, Director of Product Line Management, Merit Brass Company

3/28/2025 11:54:41 AM